Back

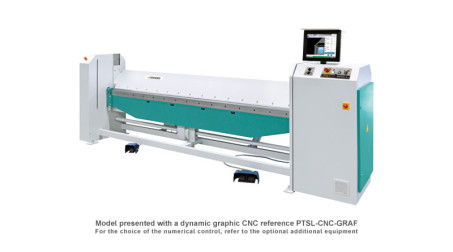

Workshop universal electric folding machines PTS

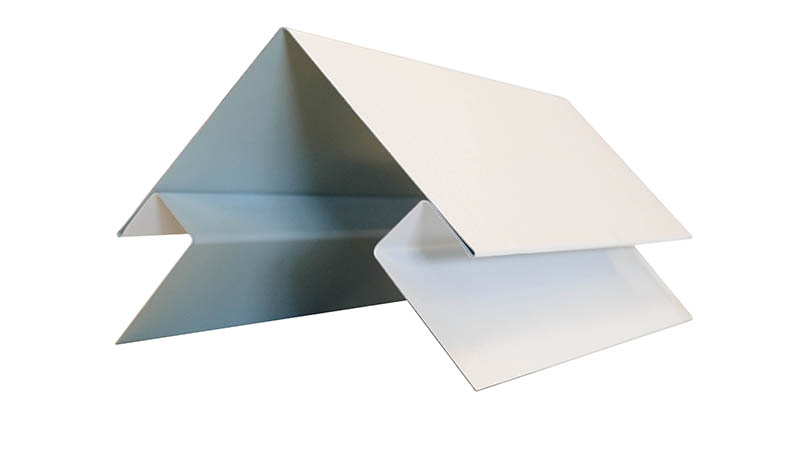

Universal electric folding machine 4m x 1mm

Ref. PTS4100-10

Price and lead time: please consult us

Universal electric folding machine for workshop, reference PTS3100-15, useful folding length 4m, 1,5mm 1050-H44 aluminum capacity - 1,0mm 400N/mm² steel capacity (capacities with 25mm folding beam tool), control by pedal and 2 interchangeable 15mm and 25mm folding beam tools supplied.

More info Optional complementary equipmentUniversal electric folding machine 4m x 1mm

> Product plus:

- Repeatability and accuracy

- Folding speed and fast-moving back gauge

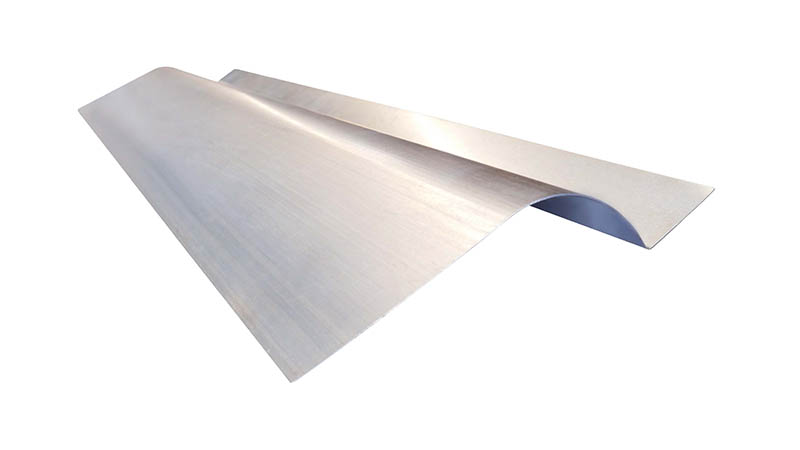

- Folding quality even for fine thicknesses

- Two types of numerical controls available

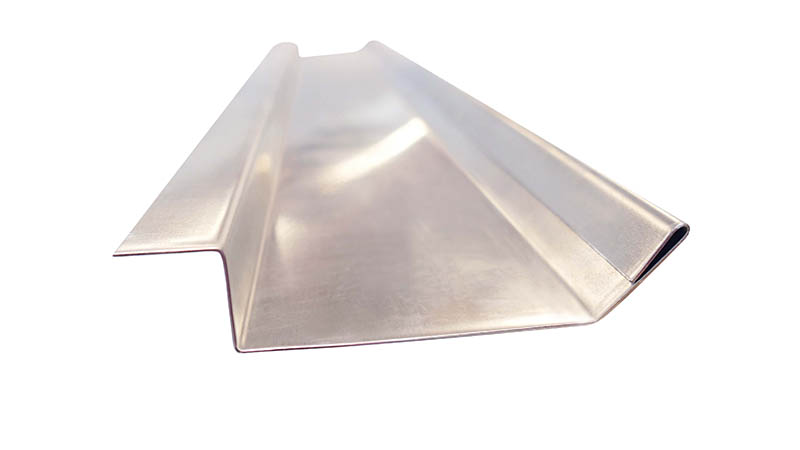

(see complementary equipment) - 2 folding beam geometries available (straight or with clearance)

(for special folding beam with clearance, see complementary equipment)

> Standard equipment:

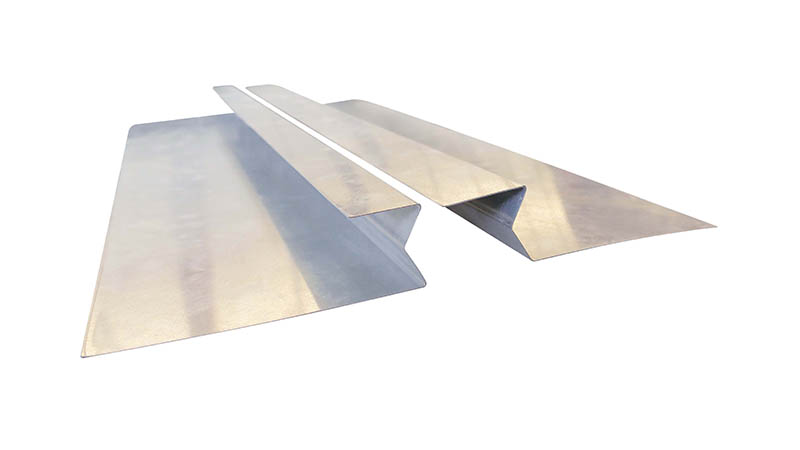

- Supply of 2 interchangeable 15 and 25mm folding beam tools

- Interchangeable clamping beam tool at 20° making easy the production of U profiles

- Folding beam crowning device

- Folding radius adjustment

- Double operator control:

- 1 main double action pedal for 1 operator

- 1 additional simple pedal in mode 2 operators

Product features

| Useful folding length (mm) |

4 100 |

|

Capacity steel 400N/mm² (mm) with folding beam 25mm |

1.0 |

|

Capacity steel 400N/mm² (mm) with folding beam 15mm |

0.8 |

|

Capacity 1050-H44 aluminum (mm) with folding beam 25mm |

1.5 |

|

Capacity 1050-H44 aluminum (mm) with folding beam 15mm |

1.0 |

| Capacity galvanized steel (mm) with folding beam 25mm | 0.8 |

| Capacity galvanized steel (mm) with folding beam 15mm | 0.65 |

| Capacity stainless steel 304L (mm) with folding beam 25mm | 0.7 |

| Capacity stainless steel 304L (mm) with folding beam 15mm | 0.55 |

|

Table height (mm) |

830 |

| Clamping beam tool angle |

20° |

| Clamp opening (mm) |

130 |

| Folding speed (°/s) | 60 |

| Clamping speed without safety light curtains (mm/s) | 10 |

| Clamping speed with safety light curtains (mm/s) | 40 |

|

Power supply (V)* |

400 V three-ph + neutral + earth |

|

Total power (kW) |

2.6 |

|

Dimensions without back gauge (mm) |

5 260 x 865 x 1 800 |

|

Dimensions with electric back gauge |

5 260 x 1 780 x 1 800 |

| Gross weight (kg) without electric back gauge |

2 900 |

|

* Electrical voltage to be specified upon order |

|

|

90° bending capacities / Minimum fold width: 15 times the thickness Clamp flattening = 1/3 of max. thickness capacity |

|

Optional complementary equipment

Shipping methods Shipping method

Delivery conditions Delivery conditions

Warranty Gaantie

Machines certified

French Origin Guaranteed

Machines certified

French Origin Guaranteed