Special machines

The expertise of a manufacturer!

A custom-made machine complying with your needs

We design and manufacture your machine for you and with you, in compliance with your specifications and your own colors. Our highly-experienced R&D department, as well as our knowledge in mechanics, hydraulics, automatism and numerical controls are our assets when we design machines with the latest technological innovations developped by Jouanel.

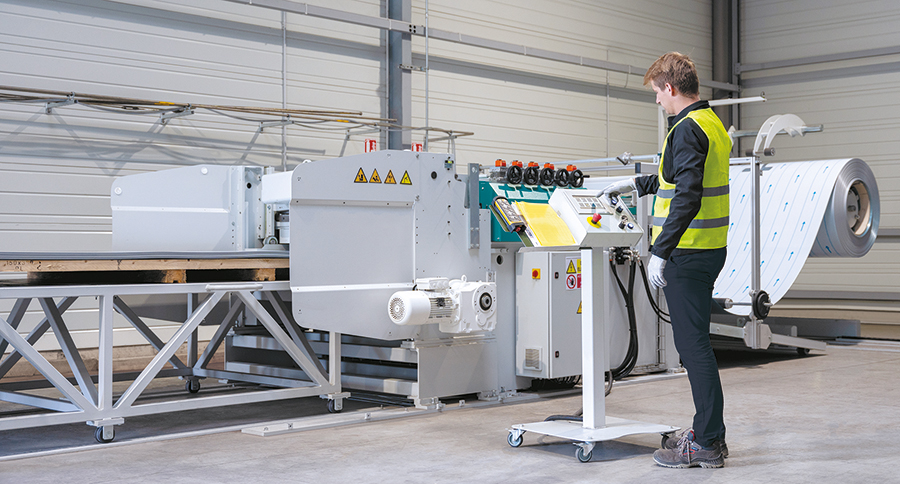

Uncoiling–Slitting–Recoiling Line

Since 1948, JOUANEL Industrie has been designing and manufacturing industrial equipment combining performance, precision, and durability. Today, we are proud to present this special slitting line, the result of our long-standing expertise and our capacity for innovation.

This high-performance line delivers exceptional precision, industrial-grade robustness, and consistent cutting quality, even on the most demanding materials.

• 100% French manufacturing

• Custom design

• Full integration into your processes

This line is the ideal solution for customers seeking reliability, longevity, and productivity.

Watch the video to discover this unique achievement, fully designed and assembled in our workshops in Sainte-Maure-de-Touraine, France.

Discover an ultra-efficient production line dedicated to the manufacturing of sandwich panels, incorporating advanced technologies for optimal efficiency.

Key Equipment and Features:

• 6-ton uncoiler with loading trolley and storage box.

• Decoiling and slitting.

• Edge rolling and interchangeable trimming.

• Shear and cutting line.

• Length cutting and sheet conveyor.

• Profiling with motorized benches.

• Inline folder for fast manufacturing of 4-sided folded panels.

Our lines are ideal for meeting the demands of industries seeking quality and productivity.

Watch the video to discover each step of the process in detail and the exceptional performance of this installation.

Our strengths

• High level of technical knowledge of our R&D

• Conformity to the technical specifications

• Quality of design and manufacture

Real partner to the industrialists, we guarantee the availability and solutions of a sole interlocutor expert in special machines, a long-term use of our machines, a quick return on investment and the reliable service of a manufacturer.

Our fields of expertise

• Decoiling-recoiling lines

• Roll-forming lines

• Slitting

• Automatic roll-bending with CNC

• Punching-Notching

• Metal Ribbing

• Special folding machines

• Standard machines adaptation

The different steps of your project

• Financial estimate incorporating your budgetary constraints

• Study of mechanics and automatism to find the solution according to the desired process

• Manufacturing the machine in our workshops

• Validation of the project

• On-site commisioning

• Training of the operator

• Technical assistance and maintenance contracts

You want to contact us

You have a project, some questions?

Our "Special machines" department manager is looking forward to hearing from you

Our online contact form > HERE

EXPORT contact

Direct line: (+33) 247 651 651

They trusted us!

- Asturienne

- AV Composites

- Bernard Bonnefond

- Biometal

- Celduc Transfo

- Cib réfrigération

- CML Fermetures

- Comat

- Decayeux

- Deme

- Esteve Production

- Frapol

- Groupe Isosta

- Johnson Bilfinger

- Loubat

- MTM

- Plasteurop

- R Bourgeois

- © Rheinzink

- Savoie Métal Toiture

- Sodistra

- Thermal Product

- Véranda Rideau

- Viesmann